Making of Kiami

Partially buried Yakusugi overgrown with moss and vegetation

Buried tree chopped and extracted.

Tree processed into blocks of lumber.

Blocks sliced under 0.1mm thick, processed, and connected into a single sheet.

Sheets cut and vertically fed into a loom.

Sheets woven together one strand at a time.

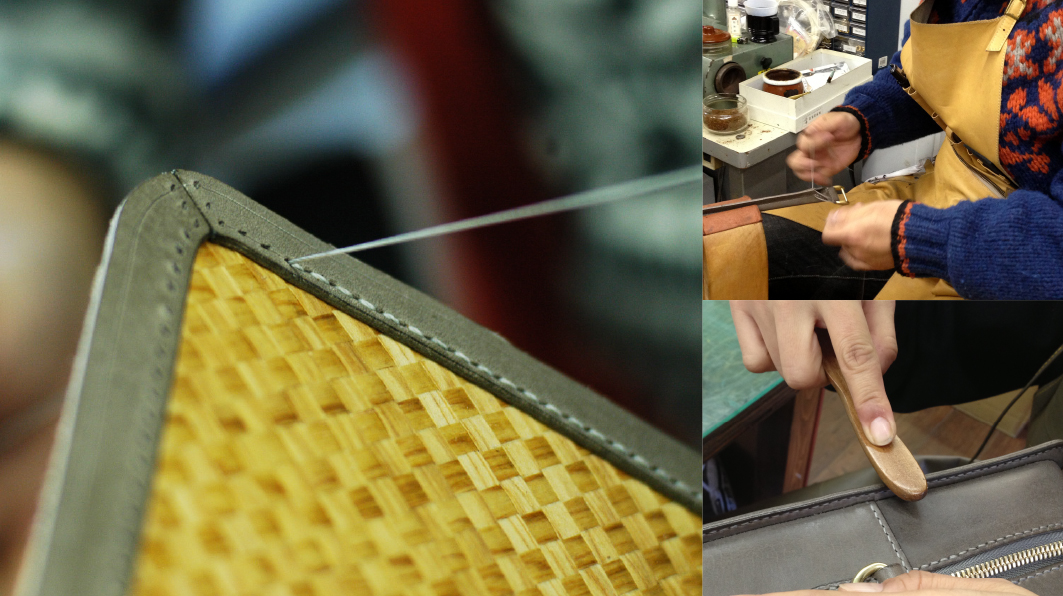

Finished Kiami sheet. Sheets with splinters, holes, or unbalanced are cut out.The useable areas are used for smaller products.

Source: Yakusugi Nature Museum

Creating products from Kiami

Kiami sheets are created by mother nature and an unimaginable length of time.

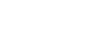

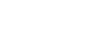

In hopes to have our customers treasure Kiami products, our highly-skilled craftsmen creates each product by hand.

Leather products are hand-sown with a high thread count and the edges are polished until they are smooth as silk.

Our craftsmen makes sure that each thread is sown with the utmost care.